Whenever highly precise and clear line indication is processing at a longer distance than hand reaching, not easy to reach with prior line drawing or printing, it would be a better solution to apply a highly bright and pure light emitted tool, such as a 635nm red line laser module. It gets constant power source supply and basic use of thermal emitting inside a durable housing tube, thus it gets superior nice heat dissipation and ultra long term lasted red laser light and red reference line projection in continuous use. Cooperated with a qualified optic lens with wide fan angles and proper adjustment of laser beam focus, red laser line generator ensures good direction, high precision and highly bright red line indication onto multiple working surfaces conveniently.

Generally line indication work might be used in multiple working environments, thus 635nm red line laser module would be processing stably as expected. It applies a durable aircraft used anodized aluminum alloy housing tube, it can bear wide range operating temperature and other mechanical moving or calibration as well. In addition, machining workshops often have high levels of dust and coolant mist. It is recommended to choose a laser line generator with a power output power of 5mW to 20mW. Too low a power output may be obscured by dust, while too high a power output may cause glare or reflections on the metal surface. Adjustments should be made based on the cleanliness of the machining environment. In dusty environments, the 10–20mW range red laser should be prioritized. Whenever line indication is processing for both long distance and high lighting, it should be selected with high power up to 150mW to 500mW so as to get ideal aligning accuracy as expected.

According to the special use of a qualified glass coated lens within 10 to 110 degree fan angles, together with adjustable focus optic lens design, 635nm red line laser module enables immediate red laser light concentration, and efficient conversion of increasing brightness and fineness red line projection at a greater distance easily. Usually high precision processes such as cutting and bending is in need of, it gets small line width of less than 0.5mm at a working distance of 500mm and a straightness error of 0.1mm/m. It is a necessity for factory workers and engineers to select correct output power and optic lens fan angle, thus it can make precise line indication for laser cutting, saw mill, wood or metal processing, textile processing industry etc.

Whatever output power it is selected, 635nm red line laser module applies a special design of APC, ACC intelligent feedback driving circuit board, it enables constant red laser light emission, and highly reliable red line indication together with other industrial machine or device. It gets no effect by increasing temperature in continuous work, but achieves long serving lifetime of more than 8,000 hours. In practical precise line positioning work fields, laser line generator gets perfect protection from cutting fluid and metal dust corrosion. It also gets vibration resistance so as to adapt to the high-frequency vibration conditions of lathes and milling machines. Being made with ultra compact size tube design, this alignment laser can be easily installed or integrated into any machine or device, achieving long term lasted and high stability line generation for all application fields.

Category: 635nm red laser module

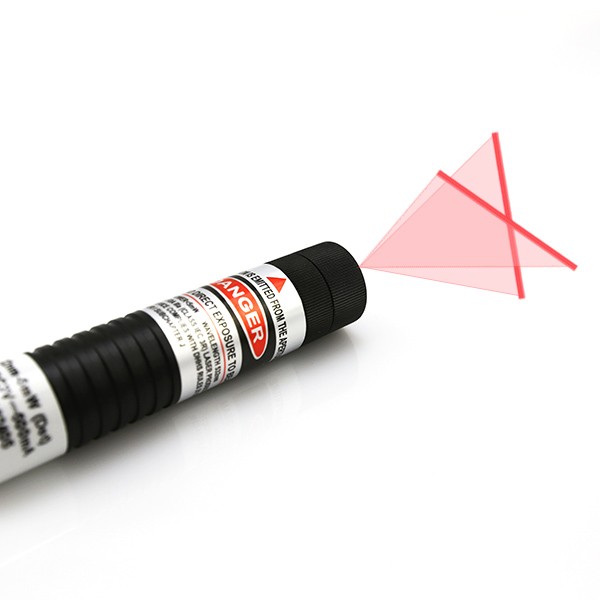

Industrial and Civil Used Gaussian Beam 635nm Red Cross Line Laser Module

Unless the use of any prior cross line drawing or printing work, in order to make sure of ultra clear, fine and precise cross line indication at various work distances, it would be an efficient job for engineers or professionals to operate a high purity light emitted tool of a 635nm red cross line laser module. Usually it applies advanced 635nm red laser diode tech and a qualified glass coated lens inside a highly durable anodized aluminum alloy housing tube. Cooperated with constant electric power source supply and proper integration with any other industrial machine or devices, this ultra compact structure made 635nm red cross laser alignment brings users ultra clear and fine two perpendicular red lines generation for all industrial and civilian application fields.

Generally 635nm red cross line laser module applies an import 635nm red laser diode within 5mW to 100mW and high power up to 150mW to 500mW as its beam emitting source. It is required to make long distance and long time lasted red line projection in distance. It gets basic use of a metal heat sink cooling system inside a durable anodized aluminum alloy housing tube. Commonly red line laser module gets adoption of a 16mm, 18mm or 26mm diameter diameter tube design, which gets larger space leaving for tube cooling down, and ultra stable red vertical and horizontal lines generation as long as 8 to 10 hours per day. Available with a wavelength of 635nm, it emits ultra bright and visible red laser light emission. It can be clearly seen at a distance of more than 25 meters and other ambient lighting occasions as well.

Owing to quite low laser beam divergence of less than 1mrad and special tem00 laser beam mode, this glass coated lens made 635nm red cross line laser module always enables ultra fine and straight two perpendicular red lines generation at long extending distances. It keeps work with only 0.3mm fineness at 10cm, and 1mm to 2mm fineness at 2 meters distance. After its easy installation or integration with industrial device or device, and proper adjustment of both of cross line thickness and cross line projecting direction, this 635nm red cross laser alignment tool brings users noncontact, no mistake and no decay light cross line alignment in continuous use.

After its easy installation onto industrial device or equipment, being made with built-in APC, ACC driving circuit board design, 635nm red cross line laser module enables constant red laser beam and two perpendicular red lines generation in continuous use. It provides static, surge, and reverse polarity protection. The service life is expected to reach 8,000 to 10,000 hours.

Applications:

Industrial Manufacturing: In automotive production, it can be used for precise robot assembly of parts such as doors, as well as for precise positioning of electronic component chips on circuit boards. In metalworking, it can be used for quality inspection and marking tasks such as steel plate cutting inspection and burr detection on plastic parts. It can also be used for machine tool leveling, conveyor belt deflection correction, and other equipment calibration.

Apparel Industry: 635nm red cross line laser module can be used for auxiliary marking of cloth cutting machines, laser marking of garment hems, and positioning of sewing machines, helping to improve cutting and sewing accuracy and efficiency.

Building and renovation: Commonly used in laser rangefinders, self-leveling laser tools, and alignment laser measuring instruments, it projects a clear red crosshair to solve problems such as straightness, flatness, parallelism, verticality, and levelness.

Medical: Highly precise red vertical and horizontal lines can be used for positioning medical equipment, such as assisting in locating the surgical area during surgery, reducing the risk of error.

Research and teaching: 635nm red laser can be used for experiments and demonstrations related to laser alignment and positioning in scientific research institutes and teaching experiments.

Multiple Industrial Dot Positioning Works with 635nm Red Laser Diode Module

In those of industrial dot positioning work fields, on consideration of high level of accuracy and highly bright dot indication onto different working surfaces, it makes an efficient job to make good use of a high purity light emitted tool of a 635nm red laser diode module. Employed by an import 635nm red laser diode and a qualified glass coated lens inside a durable metal housing tube, connected with an external electric power source and basic use of thermal emitting system design, 635nm red dot laser enables high energy density red light emission at long extending distance, and converts into increasing accuracy and bright red reference dot projection onto multiple working surfaces.

In various industrial dot positioning works, 635nm red laser diode module is projecting a highly visible red dot as an optical reference point to quickly align workpieces, tools, or assembly lines, achieving non-contact, precise positioning. It adopts an AC/DC adapter as its electric power source, not spending extra time on alkaline battery power source, it just makes constant red laser beam and red reference dot projection continuously. Usually red laser dot projection is intuitively visible, eliminating the need for operators to repeatedly measure with tools like rulers and calipers. Alignment can be determined in seconds, significantly reducing process setup time.

When 635nm red laser diode module keeps work with high transmittance and high energy density red laser beam emission directly from an import 635nm red laser diode within 5mW to 500mW, equipped with a qualified glass coated lens in front of beam aperture, it always makes highly clear and precise red reference dot projection at various work distances and multiple lighting occasions. When it gets quite low laser beam divergence of less than 1mard and special TEM00 laser beam mode, whatever working surface it is pointing, this 635nm red dot laser alignment generates ultra compact size and highly bright red reference dot projection.

Equipped with intelligent feedback controlled APC, ACC driving circuit board design, no matter long time time and whatever output power it is selected, 635nm red laser diode module keeps work with minimal red laser beam spot drift of less than 0.1mm per meter, and is unaffected by environmental factors such as mechanical vibration and oil contamination. Positioning errors can be controlled within 0.1-0.5mm. It operates stably in a wide industrial temperature range of -20°C to 60°C. Its red light has superior penetration to other visible light sources, ensuring the red dot remains clear even in normal workshop lighting or lightly dusty environments.

General applications in industrial dot positioning fields:

Machining Positioning: For example, on milling machines and lathes, the red alignment laser dot marks the center point of the cut/drill hole to be cut, helping the tool quickly align with the workpiece reference point to avoid misaligned cuts.

Production Line Material Alignment: In food and pharmaceutical packaging lines, the red dot locates the sealing line and label placement of packaging boxes, ensuring consistent packaging positioning for each batch.

Automated Equipment Calibration: Before an industrial robotic arm grasps a workpiece, the red laser diode module can mark the grip center point, assisting the robotic arm in precise positioning. Alternatively, the red dot can be used to correct conveyor belt deviation, serving as a reference line to determine if the material has shifted.

Welding Positioning: When welding steel structures and automotive parts, the red laser dot marks the weld starting point and path reference, preventing workpiece scrap caused by deviation.

How Can 635nm Red Cross Line Laser Module Be Used in The Machining Industry

In any type of high precision and high brightness cross line projection at a longer distance than formal hand reaching, not able to rely on prior cross line drawing or printing work, a lot of engineers and professionals would prefer to operate a high energy density beam emitted tool of a 635nm red cross line laser module. The projected red cross line laser source gets the featured advantages of high direction and good monochromatic, capable of focusing to a very small spot. This allows for micron-level precision positioning, meeting the high-precision requirements of machining. Based on its correct use of output power and optic lens fan angle, and proper integration with industrial device or equipment, this ultra compact structure made red cross laser alignment enables low production cost, easy reaching and highly precise cross line generation onto multiple working surfaces conveniently.

Comparing with 650nm red laser, the usual use of a 635nm red cross line laser module gets much shorter wavelength, which enables at least 3 times brighter red laser light emission. Further more, owing to its low laser beam divergence of less than 1mrad and special TEM00 laser beam mode, it gets ultra fine and bright two perpendicular red lines generation at various work distances and multiple ambient lighting occasions as well. In practical cross line measuring works, based on the use of a metal heat sink cooling system inside a highly durable anodized aluminum alloy housing tube, this Pro red cross laser alignment gets good heat dissipation. It can maintain stable output power and minimal wavelength drift over long periods of operation, resulting in a lifespan of over 12,000 hours.

When cross line alignment is processing at a longer distance than formal hand reaching, this purity light emitted 635nm red cross line laser module just shows its superiority. It applies a qualified glass coated lens with 10, 15 and 110 degree fan angles and adjustable focus optic lens inside its durable metal housing tube. When it projects highly fine and bright two perpendicular red lines within 0.5 meter to 6 meters length, it is not only used for natural lighting occasion, but also making satisfied cross line measurement within 25 meters and high lighting working environments as well. Red cross lines can be easily observed by human eyes in brightly lit production environments, facilitating quick and accurate positioning.

Being made with durable anodized aluminum alloy housing tube design, this 635nm red cross line laser module gets special shock resistance performance, which operates stably even on heavy machinery and withstands the complex vibration environment of machining workshops. It is suitable for a wide range of applications, including woodworking machinery, sheet metal shearing and pressing machines, tire building machines, and shoemaking machines. It can also process a wide range of materials, including metals, plastics, and ceramics, offering exceptional processing flexibility for cutting, welding, and marking.

Applications in the machining industry:

Machine tool setting assistance: This 635nm red cross line laser module can be installed on lathes, milling machines, and other machine tools to project cross lines onto the workpiece, helping operators quickly and accurately determine the relative position of the tool and workpiece, reducing tool setting time and improving machining accuracy.

Part assembly positioning: In scenarios such as automotive production lines, red alignment laser acts as the “eyes” of the robotic arm, projecting red cross lines to enable robots to precisely install parts like car doors, with an error controllable within 0.5mm.

Equipment calibration: Crosshairs projected on CNC machine tools can be used to calibrate the X/Y axes for absolute parallelism. On conveyor belts, crosshairs can be used to indicate belt deviation, facilitating quick adjustments.

Quality Inspection Marking: After cutting steel plates, a crosshair projection can be used to quickly verify the verticality of the cut edges. For plastic parts, a red line can be used to mark the product edge, making it easier to detect defects such as burrs through a magnifying glass.

How Can High Straightness 635nm Red Line Laser Module Work Precisely

Whatever kind of working surfaces users are trying to make ultra fine, clear and precise line indication, on consideration of high level of accuracy and high speed line positioning works, it would be a quite efficient solution to apply a high energy density device of a 635nm red line laser module. It keeps work with highly straight and good linear quality red reference line projection from beam aperture. Based on its correct use of output power and optic lens fan angle, and proper installation or integration with industrial device or equipment, being used as an accessory part, this ultra compact size tube made red laser line generator always makes excellent red line indication onto multiple raw material surfaces precisely.

According to the adoption of an import 635nm red laser diode within 5mW to 100mW and high power up to 150mW to 500mW, this red line laser module gets special use of a qualified glass coated lens within 10 to 110 degree fan angles and metal heat sink cooling system inside its durable anodized aluminum alloy housing tube. In practical precise line positioning work, it gets superior nice heat dissipation, high stability, strong anti-interference capabilities, and excellent consistency, ensuring stable output power. Owing to its selected output power, besides its operation for close distance and inner room precise line positioning work, this red laser line generator also enables highly precise and clear red line indication at long extending distance of 25 meters and multiple lighting occasions as well. This sensitive color laser light emitted laser line alignment tool makes excellent line positioning results under formal lighting and other high lighting occasions as well.

In practical precise line positioning work fields, owing to the use of a durable anodized aluminum alloy housing tube design, this 635nm red line laser module always emits high quality red Gaussian beam. Configured with adjustable focus optic lens, once highly intense red laser light is concentrated, it just converts into an increasing accuracy and fineness red line at longer distance easily. The casing offers high strength and wear resistance, can withstand certain impacts and vibrations, and is resistant to static electricity.

General applications of 635nm red line laser module:

Industrial Manufacturing: In electronics manufacturing, it can be used to check the alignment of circuits and solder joints during PCB inspection. In chip packaging, red laser line can be used to mark low-reflective surfaces. In machining, it can be used for tool setting and material cutting positioning. Furthermore, laser line generator can be used for conveyor positioning, centering packages or parts, and as a sensor trigger source for synchronized marking of photoelectric switches.

Construction Engineering: 635nm red laser line generator can be used for rough indoor positioning, such as providing a reference line for tile laying and drywall installation. It can also be used for short-distance layout, marking walls and floors within 5 meters.

Educational Demonstration: In physics experiments, Red alignment laser line can be used to demonstrate the rectilinear propagation and refraction of light. In engineering training, they can serve as an auxiliary tool for teaching basic calibration of mechanical equipment.

Medical: Can be used in medical equipment, for example, as an auxiliary light source for accurate physical positioning of lasers, helping doctors perform more precisely.

Security: Can be used as a simple cordon for low-power warnings in warehouses, exhibition booths, and other locations. It typically requires use with a detector.

Analysis of Industrial Field Applied Tool of 635nm Red Cross Line Laser Module

In any type of long time lasting and long distance pointed cross line alignment work, no matter it is processing at close or long work distance, it would be a quite nice experience for operator to select a high brightness beam emitted tool of 635nm red cross line laser module. It applies an import 635nm red laser diode and a qualified optic lens inside its durable housing tube. Red laser beam has good direction and the red cross lines it emits are highly collimated, which can provide accurate positioning reference for industrial production, ensure that processing or operation is carried out according to the preset position, and improve product accuracy. Whenever cross laser alignment tool makes proper installation and adjustment to correct position, it brings users high precision, high speed and long time lasting cross line indication for all precise machinery processing works effectively.

The adoption of the wavelength of 635nm has a higher visual brightness at the same power while comparing with formal 650nm red laser with the same output power. The basic use of a 635nm red cross line laser module applies an import 635nm red laser diode within 5mW to 100mW and high power up to 150mW to 500mW as its beam emitting source. Basically it applies an inner metal heat sink cooling system inside a durable anodized aluminum alloy housing tube, after the adoption of different dimension tube design of 16mm, 26mm diameter for different output power range, this cross laser alignment tool always gets sufficient space leaving for heat dissipation and ultra stable and clear red vertical and horizontal lines generation in long time use. Even though cross line alignment is processing at a longer distance or in an industrial environment with complex light, the red cross lines can be clearly seen, which is convenient for operators to observe.

Equipped with an AC/DC adapter, this glass coated lens made 635nm red cross line module generates highly straight and fine two perpendicular red lines with accurate 90 degrees and different dimension. It is equipped with high performance drive circuits, which has the characteristics of strong anti-interference and good consistency. It can work stably for a long time and are not easily affected by external factors and cause light decay or unstable light. With the assistance of a laser alignment mounting bracket, this small size cross laser alignment tool can be easily installed on the vertical or horizontal plane of various industrial equipment, and the laser line can be fine-tuned in three-dimensional space at will, and can be quickly adjusted to the best use state. Under normal working conditions, the service life can reach thousands of hours or even longer, reducing the cost of equipment maintenance and replacement.

Application fields:

Tire production: 635nm red cross line laser module can be installed on radial tire forming machines and bias tire forming machines for tire production positioning, which can play an important role in improving tire quality, quality preservation, increasing production, and reducing consumption.

Textile and clothing: Red cross line source is often used in clothing cutting beds to provide accurate positioning references for fabric cutting, helping workers to cut according to the markings, and improving cutting accuracy and efficiency. It can also be used in embroidery machines, printing machines and other equipment to ensure that the pattern is embroidered or printed accurately.

Mechanical processing: Red cross line laser is suitable for metal sawing machines, PCB circuit board cutting machines, etc., to provide positioning guidance for the cutting process, make the cutting path more accurate, reduce material waste, and improve processing quality and efficiency.

Woodworking industry: 635nm red alignment laser can be installed on woodworking machinery, such as saw blade machines, etc., to help woodworkers accurately determine the cutting position and angle, improve the accuracy and consistency of wood processing, and reduce the defective rate.

Advantageous Use of 635nm Red Laser Line Generator for Industrial Processing

What is an efficient job to make sure of ultra clear, fine and accurate line indication at different work distances? Some of workers and engineers would prefer to make use of a high energy density device, such as a 635nm red laser line generator. It applies a qualified import 635nm red laser diode and a glass coated lens with different fan angle inside a highly durable metal housing tube. After its proper connects with an external electric power source, not relying on any manual labor force input or prior line drawing work with traditional manual or mechanical line measuring works, the real use of a 635nm red line laser module always assures high precision, high fineness and highly straight red line indication onto all working surfaces conveniently.

The basic use of a 635nm red laser line generator should be working for a quite long time, thus it is a major part to maintain its reliable stability in continuous use. The industrial grade laser module applies a durable anodized aluminum alloy housing tube, which has good vibration resistance and temperature resistance. Cooperated with an inner metal heat sink cooling system, it obtains superior nice heat dissipation and thermal conductivity. During long time lasting continuous line positioning work, red laser beam output is stable, reducing the deviation of the marking line caused by equipment jitter or environmental changes.

Owing to its a bit shorter wavelength than 650nm or 660nm wavelength red laser, red laser line emitted from a 635nm red laser line generator has high contrast on the surface of industrial materials such as metal, wood, and cloth. Even in the complex light environments of the workshop, such as strong light and shadow, the human eyes can quickly and clearly identify the red reference line and reduce visual fatigue. According to basic measurement and experiment of desired line length, line fineness and work distance from beam aperture to targeting surface, this 635nm red line laser module enables correct choices of output power and optic lens fan angle. The straight red reference line has good linear quality and sharp edges, which can achieve millimeter-level or even higher precision benchmark marking, directly reduce the error of manual alignment, and improve processing consistency.

Comparing with traditional tools, such as tape measures and ink lines, no repeated measurement and calibration is required, and preparation time is shortened, 635nm red laser line generator is especially suitable for standardized operations in mass production. In various industrial precise machinery processing works, red laser line alignment work is compact and can be flexibly installed on various processing equipment (cutting machines, cutting beds, bending machines, etc.), and can adjust the line length and line width according to processing requirements to adapt to workpieces of different sizes.

In various industrial machinery processing works, 635nm red laser line generator can be used in precise positioning and marking works, such as pre-marking of cutting path during metal cutting, reference line for plate cutting during wood processing, alignment mark for cloth cutting, angle positioning for pipe bending, etc., which can provide intuitive visual guidance for processing operations. When alignment laser is operated with high power up to 50mW for longer distance and high lighting line measuring works, it is a major part to take active laser safety measures and wear correct laser safety goggles so as to achieve easy, secured and no track measurement for all working occasions effectively.

Major Introduction of 635nm Red Laser Diode Module In Industrial Field Use

Whenever users are trying to make ultra clear and precise dot indication for various industrial mechanical processing works, not limited by long distance, high height and other complex working environments etc, it would be the best chance for engineers or factory workers to operate a high purity and high brightness light emitted tool of a 635nm red laser diode module. It gets featured advantages of clear red dot emission, low laser beam divergence, good collimation. Any time it makes correct use of output power and operating voltage electric power source supply, this red dot laser is able to make highly clear red dot positioning onto desired working surfaces. Comparing with traditional dot measuring works, it can greatly reduce the error and loss in the production process.

Usually 635nm red laser diode module adopts the original import 635nm red laser diode within 5mW to 100mW and high power range of 150mW to 500mW, with the intelligent feedback control circuit board in type of APC, ACC. Cooperated with an inner metal heat sink cooling system, whatever output power it is selected, it is working well with high efficiency transmission optical system which has the characteristics of low power consumption and high-efficiency optical power output, good consistency, long service life, and can work stably for a long time in an industrial environment. This 635nm red dot laser alignment tool gets no effect by increasing temperature and serious electric current impact, and enables long time lasting red dot indication for multiple raw material processing works.

When 635nm red laser diode module gets proper connects with 5V, 9V, 12V 1000mA DC power supply, it begins to work with continuous red laser beam emission intensely. In addition, if users are getting special use of continuous laser light source emission, it can also be designed with inner battery power source supply. When it makes constant red reference dot projection within daily operating time of 8 to 10 hours per day, it can reach up to 85% laser beam stability and highly clear red dot indication for multiple raw material processing works conveniently. It is always easy to install and disassemble, and can be quickly deployed and used in a variety of scenarios.

Owing to its special design of thermal emitting and durable housing tube design, the real use of a 635nm red laser diode module gets strong industrial applicability, which can work in a variety of environments, can adjust the brightness, adapt to different material surfaces and ambient light, and can also play a certain protective role for human eyes. When it is installed in various equipment, it does not take too much space, and is conducive to the compact design of equipment. After correct use of output power and proper integration to correct position, it can bring users a lot of convenience for those of industrial fields as below:

Laser processing equipment positioning: 635nm red laser diode module is commonly used in laser marking machines, laser welding machines, laser engraving machines and other equipment to provide accurate position indication for processing, so that marking, welding, engraving and other operations can be carried out according to the predetermined position, improving processing accuracy and quality.

Machine tool processing assistance: ultra compact structure made red dot laser can be installed on the machine tool to help operators quickly and accurately determine the processing position and size of the workpiece, assist in operations such as tool setting, reduce debugging time, and improve processing efficiency.

Four-wheel alignment: in the four-wheel alignment instrument in the automobile maintenance industry, red alignment laser is used to indicate the position and angle of the wheel, helping technicians to adjust the wheel alignment parameters more accurately and ensure the driving performance of the vehicle.

Clothing processing marking: red laser light source can be used for clothing button point light source positioning, cloth cutting auxiliary marking, sewing machine auxiliary marking positioning, etc., to help workers more accurately perform cutting and sewing operations, and improve the accuracy and efficiency of clothing production.

General Applications of 635nm Red Laser Diode Module for Multiple Fields

Unlike the use of any prior dot positioning work, not any longer limited by long distance, long time or other hard reaching places use, none of manual or mechanical dot projecting tool can be comparable with a high density beam emitted tool of a 635nm red laser diode module. It applies a formally available 635nm wavelength red laser diode among visible red laser light band, the human eye is sensitive to this wavelength, the red dot is clear and easy to see, and it is suitable for short distance dot indication. On condition that red dot laser gets constant electric power source supply and proper integration with those of industrial machine or device, it brings users quite easy reaching, good direction and ultra clear red reference dot projection onto different working surfaces conveniently.

When 635nm red laser diode module gets low laser beam divergence of less than 1mrad and special Tem00 laser beam mode, it always projects ultra compact size and highly bright red reference dot onto different working surfaces. For instance, it gets only 0.3mm dot diameter at 10cm, and 1mm to 2mm dot diameter at 2 meters work distance. In addition, employed by an import 635nm red laser diode within 5mW to 100mW, and high power up to 150mW to 500mW, this dot laser alignment is applying different dimension metal housing tube design, thus there is always larger space leaving for tube cooling down and heat dissipation. In those of long time lasting red laser dot projection within 8 to 10 hours per day, it enables highly stable red dot projection and ultra high laser light cycling use in continuous use.

After configuration with a 16mm, 18.9mm and 26mm diameter anodized aluminum alloy housing tube, this ultra compact size tube made 635nm red laser diode module enables quite easy installation, quick reaching and no barrier red dot indication onto any vertical or horizontal surface. It has high integration and is easy to embed into small devices, such as laser pens and scanners. Owing to its its low energy consumption and low relying on manual labor force input, according to correct use of output power and operating voltage electric power source supply, this direct diode emission made 635nm red dot laser alignment tool just brings users ultra clear and precise dot alignment for multiple lighting occasions effectively.

Applications:

Industrial field: highly precise dot indicating tool of a 635nm red laser diode module is used for laser positioning, such as machine tool processing, position calibration of cutting equipment,, laser marking (production line alignment), using the visibility of red dots to improve operation accuracy.

Consumer electronics: ultra compact size tube made red dot laser is commonly used in laser pens, projection keyboards, or as indicator lights for electronic devices (such as projectors, barcode scanners).

Medical and scientific research: low-power red alignment laser can be used for optical experiments, biological cell observation (auxiliary positioning), and some medical equipment (such as skin treatment instruments) also use its visible light indication function.

Security and measurement: laser sights (toys or simulation equipment), distance meters (marking target points with red dots).

High Accuracy Aligned 650nm Red Cross Line Laser Module

Unlike the formally used 635nm red laser, the genuine use of a 650nm red line laser module makes the best use of a 650nm red laser diode, which is not only getting a bit longer wavelength, but also getting even more stable and reliable laser beam emission in long time use. Being made with a qualified optic lens with different fan angles and thermal emitting system, configured with a highly durable metal housing tube and constant electric power source supply, this direct diode emission made device of a red laser alignment tool enables ultra clear and stable two perpendicular red lines generation at long extending distance and multiple lighting occasions conveniently.

When 650nm red cross line laser module gets constant electric power source from an external AC/DC adapter, comparing with a formally used alkaline battery power source, it is always keeping work with continuous red laser beam emission from an import red laser diode within 5mW to 100mW and high power up to 150mW to 500mW. It is configured with the most important design part of APC, ACC driving circuit board inside its high duration anodized aluminum alloy housing tube. When it keeps work with long time lasting red vertical or horizontal lines generation in long time use, it still maintains ultra stable performance under multiple working environments, including wide operating temperature, different humidity, mechanical calibration etc.

In various industrial precise device manufacturing work fields, employed by a qualified glass coated lens with 10, 15 and 110 degree fan angles, this 650nm red cross line laser module is emitting high visibility and high precision positioning results. It provides efficient and accurate supports for all mechanical processing work fields effectively. For instance, in metal cutting, drilling and other processing links, this 650nm red cross laser alignment tool projects red cross line sources to make accurate mark for all processing position works. Whatever working surface it is pointing, it can reduce debugging time, improve processing accuracy, reduce scrap rate, and improve production efficiency.

This 650nm red cross line laser module generates different dimension red cross line lengths within 0.5 meter to 6 meters in use. The advanced use of adjustable focus optic lens enables highly concentrated red laser light emission and efficient conversion of increasing fineness and brightness red cross line projection in distance. It enables quite easy installation and integration onto other machine or device, and makes ultra clear and precise measurement for high tech and lab experiments works.

When it makes advanced use of APC, ACC driving circuit board, this 650nm red cross line laser module makes constant red laser beam and red cross line source generation from beam aperture. It is not effected by increasing temperature and serious electric current impact as well, and achieving long serving lifetime in proper use.